In modern drilling operations, wellbore integrity isn’t just a box to check. It’s a foundational requirement for success. Defined as the ability of a well to maintain its structural and pressure-containment integrity over its lifecycle, wellbore integrity directly impacts safety, efficiency, and production outcomes.

When integrity is compromised, the consequences can be immediate and severe: formation instability, lost circulation, and well control failures that lead to costly delays or catastrophic incidents. These risks are magnified in today’s increasingly complex reservoirs, where pressure windows are narrow and downhole conditions can shift rapidly.

That’s why leading operators are turning to proactive wellbore integrity solutions to stay ahead of these challenges. By combining advanced wellbore technologies with real-time pressure management tools such as Managed Pressure Drilling, operators can actively prevent issues before they escalate. The result? Safer, more stable wells and drilling operations that stay on track.

In this post, we’ll explore how wellbore integrity services contribute to drilling success, and why proactive pressure control is no longer optional—it’s essential.

Understanding Wellbore Integrity

Wellbore integrity refers to the ability of a well to maintain both structural soundness and pressure containment throughout its operational life. It involves more than just quality casing and cementing. True integrity requires a system-level approach that accounts for the dynamic conditions encountered during drilling, completion, and production.

When wellbore integrity is maintained, it protects personnel, equipment, and the environment for consistent and reliable performance. Without it, the risk of uncontrolled flow, formation collapse, or hazardous fluid migration increases significantly, putting the entire operation at risk.

The threats to integrity are varied and often interrelated. Narrow pressure margins, unstable formations, pore pressure fluctuations, and temperature extremes all place stress on the well structure. Inadequate pressure control can exacerbate these risks, leading to failure points that are costly and dangerous to remediate.

Addressing these challenges requires the right combination of wellbore technologies and field-proven practices. That’s where comprehensive wellbore integrity services come in, delivering the tools, insight, and responsiveness needed to anticipate and mitigate threats before they impact the well.

The Role of Managed Pressure Drilling in Pressure Control

Managed Pressure Drilling plays a central role in maintaining wellbore integrity by giving operators precise, real-time control over downhole pressures. Unlike conventional pressure control methods, which rely on static mud weight and reactive adjustments, Managed Pressure Drilling is an adaptive approach that continuously balances formation pressure with surface-controlled backpressure.

This level of control allows for earlier detection of subtle pressure changes that may indicate influxes, losses, or wellbore instability. By managing these variations proactively, Managed Pressure Drilling reduces the likelihood of kicks, lost circulation events, and costly downtime. It also improves the ability to drill within tight pore and fracture pressure windows, which is increasingly necessary in today’s complex reservoirs.

More than just a technology, Managed Pressure Drilling is part of a broader class of drilling solutions focused on prevention rather than response. It enables crews to make real-time adjustments as conditions evolve, helping to keep the well in a stable and productive state throughout the operation.

Related Reading: How Lean Workflows Help Reduce Non-Productive Time with Managed Pressure Drilling

Proactive pressure control is one of the most effective ways to safeguard wellbore integrity throughout drilling operations. By anticipating and managing pressure-related challenges before they escalate, operators can avoid many of the most common causes of well failure.

One of the key benefits is the ability to prevent formation instability. When downhole pressures are not properly managed, fragile formations can collapse or wash out, compromising the well structure and increasing the risk of stuck pipe incidents or unplanned sidetracks. Proactive pressure control helps maintain stability across varying lithologies and pressure regimes.

It also plays a critical role in minimizing lost circulation events. By staying within the narrow margin between pore and fracture pressure, operators can prevent mud losses that delay operations, reduce hole cleaning efficiency, and complicate cementing.

Kick detection and response are also greatly improved. With real-time visibility and control, crews can identify abnormal pressure trends early and make adjustments immediately, reducing the risk of blowouts and other serious well control events.

These benefits are central to wellbore integrity solutions, which combine pressure control, advanced monitoring, and responsive decision-making to help safeguard operations and streamline performance. By addressing potential issues early, operators can reduce non-productive time with drilling solutions that are safer and more cost-effective.

Benefits of Proactive Pressure Control

Proactive pressure control is one of the most effective ways to safeguard wellbore integrity throughout drilling operations. By anticipating and managing pressure-related challenges before they escalate, operators can avoid many of the most common causes of well failure.

One of the key benefits is the ability to prevent formation instability. When downhole pressures are not properly managed, fragile formations can collapse or wash out, compromising the well structure and increasing the risk of stuck pipe incidents or unplanned sidetracks. Proactive pressure control helps maintain stability across varying lithologies and pressure regimes.

It also plays a critical role in minimizing lost circulation events. By staying within the narrow margin between pore and fracture pressure, operators can prevent mud losses that delay operations, reduce hole cleaning efficiency, and complicate cementing.

Kick detection and response are also greatly improved. With real-time visibility and control, crews can identify abnormal pressure trends early and make adjustments immediately, reducing the risk of blowouts and other serious well control events.

These benefits are central to wellbore integrity solutions, which combine pressure control, advanced monitoring, and responsive decision-making to help safeguard operations and streamline performance. By addressing potential issues early, operators can reduce non-productive time with drilling solutions that are safer and more cost-effective.

Long-Term Impact on Well Performance

The benefits of wellbore integrity don’t end once drilling is complete. In fact, the decisions made during the planning and drilling phases directly influence how the well performs over time. Wellbore integrity services are essential not just for safe operations, but for setting the foundation for long-term reliability and production success.

Wells with compromised integrity often face higher rates of intervention, increased fluid migration, and reduced reservoir contact—issues that can all limit recovery and shorten asset life. By contrast, maintaining integrity from the start allows for smoother completions, better stimulation efficiency, and more consistent flowback.

There’s a clear link between proactive pressure control and well production optimization. When a well is drilled with minimal damage to the formation and maintains structural soundness, operators can expect better overall performance with fewer disruptions. That translates to lower operating costs, higher production rates, and improved return on investment.

This is where proven wellbore technologies come into play. From real-time monitoring systems to precision-controlled pressure management, each element supports better outcomes not just today, but across the full lifecycle of the well.

Why the Stasis Approach Makes the Difference

At Stasis Drilling Solutions, wellbore integrity isn’t a service line—it’s a guiding principle. Our team combines deep field experience with a hands-on understanding of Managed Pressure Drilling and pressure control challenges in complex wells. That expertise drives every solution we deliver, from planning to execution.

Our wellbore integrity services are built around responsiveness and adaptability. We deploy specialized teams that work directly within your operations, bringing practical insight and intelligent pressure control strategies tailored to your formation and drilling objectives.

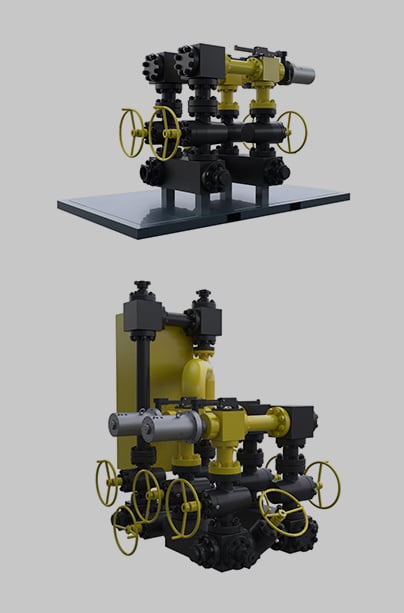

Stasis applies advanced wellbore technologies and real-time monitoring systems that enable operators to make smarter, faster decisions. From our intelligent control system to our boots-on-the-ground support, every component is designed to reduce risk, optimize drilling performance, and protect long-term well productivity.

The result is a complete package of drilling solutions that prioritize safety, reduce downtime, and deliver performance across the well’s lifecycle.

Conclusion

In today’s drilling environment, proactive pressure control isn’t just a best practice. It’s a requirement. The risks of formation instability, lost circulation, and well control failures are too significant to address reactively. Instead, forward-thinking operators are investing in wellbore integrity solutions that identify and manage threats early, keeping operations safer, more efficient, and more productive.

At Stasis Drilling Solutions, we understand the value of strong foundations. Our approach combines advanced wellbore technologies with real-time control and practical, field-tested knowledge to deliver results that last. From minimizing risk to supporting long-term performance, we help operators drill smarter, recover more, and get the most out of Managed Pressure Drilling.

Learn how the wellbore integrity services from Stasis support better drilling outcomes.

Let’s talk about taking control of pressure from the start.