Advancing Sustainable Drilling with MPD

The oil and gas industry faces growing pressure to reduce environmental impact while maintaining safety and efficiency. Stricter regulations and increasing demand for sustainable drilling practices require operators to adopt advanced technologies that optimize performance while ensuring compliance.

Effective drilling requires precise wellbore pressure control, spill prevention and reduced resource consumption. Traditional methods often struggle with fluid losses, blowouts and inefficient well control, leading to environmental risks, higher emissions and regulatory challenges.

Stasis Drilling Solutions leads the industry in Managed Pressure Drilling (MPD) technology, delivering real-time flow monitoring, automated pressure control and wellbore integrity solutions. These innovations help drilling operators reduce environmental risks, optimize efficiency and meet compliance standards.

How MPD Technology Drives Safer, More Sustainable Drilling

What is managed pressure drilling?

Managed Pressure Drilling (MPD) is an advanced wellbore pressure control method that dynamically adjusts pressure in real time. Unlike traditional drilling, which relies on static mud weight, MPD optimizes pressure control, preventing well control incidents and minimizing environmental risks.

MPD technology plays a key role in reducing the environmental footprint of drilling operations. Here’s how:

- Prevents blowouts and fluid spills: Precise pressure control minimizes the risk of uncontrolled influxes or losses, preventing hazardous spills and emissions.

- Reduces drilling fluid usage: Optimized pressure management reduces fluid consumption, lessening the environmental burden of fluid production, transportation and disposal.

- Lowers carbon emissions: Faster, more efficient drilling reduces fuel consumption and emissions from rig operations.

- Enhances wellbore stability: Wellbore integrity solutions prevent formation damage and contamination, protecting surrounding ecosystems.

By integrating MPD technology, Stasis enables operators to achieve safer, cleaner and regulation-compliant drilling operations.

Stasis’ MPD Technology: Reducing Environmental Risks and Optimizing Drilling

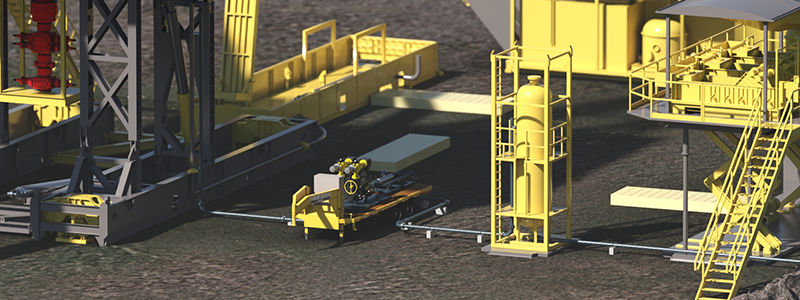

Stasis delivers advanced MPD technology that enhances drilling safety, efficiency and sustainability. By integrating automated pressure control, high-accuracy flow monitoring and real-time wellbore analysis, Stasis ensures better environmental protection and regulatory compliance.

IMPACCT™ MPD Control System: Automation for Safer Drilling

The IMPACCT™ MPD Control System enables real-time, automated pressure adjustments, helping drilling operators prevent spills, reduce emissions and optimize drilling efficiency. This integration ensures greater compliance with environmental regulations while offering other key benefits such as:

- Prevents fluid losses and uncontrolled releases with instant pressure adjustments.

- Minimizes human error, enhancing safety and regulatory compliance.

- Reduces excessive drilling fluid use, lowering waste and emissions from rig operations.

Flow Measurement System: Real-Time Wellbore Integrity Monitoring

Fluid management is critical for sustainable drilling operations. Stasis’ Flow Measurement Systems instantly detects fluid imbalances, helping MPD drilling companies meet or exceed environmental compliance requirements. It ensuring:

- Real-time wellbore monitoring, preventing hydrocarbon spills and environmental contamination.

- Accurate wellbore stability analysis, reducing formation damage risks.

- Optimized drilling performance, lowering resource waste and environmental impact.

Expert Engineering for Compliance and Efficiency in MPD Drilling

Beyond advanced MPD technology, Stasis provides expert engineering services to help drilling operators integrate MPD systems while maintaining environmental compliance. Inefficient MPD integration can extend drilling times, increase emissions and waste valuable resources, making precise rig integration essential for sustainable operations.

Stasis develops customized MPD integration plans, ensuring each system is tailored to the rig’s requirements. These plans enhance wellbore stability and pressure control, optimizing drilling efficiency, reducing total energy consumption and minimizing environmental risks. As a result, operators avoid costly delays, stay on schedule and reduce emissions.

Stasis also offers comprehensive regulatory compliance support, helping drilling companies navigate complex environmental regulations. With 24/7 remote technical support, onsite supervision and wellbore stability analysis, Stasis helps ensure operations remain within regulatory limits. Through ongoing operator training and expert consultation, drilling teams are equipped with best practices for environmentally responsible drilling, ensuring long-term compliance and efficiency.

By combining cutting-edge engineering, tailored rig integration and regulatory expertise, Stasis enables operators to reduce their environmental footprint while maintaining high performance and compliance.

Stasis: Leading the Future of MPD Innovation for Sustainable Drilling

Stasis continuously invests in MPD technology advancements, setting the industry standard for safe, efficient and sustainable drilling.

By developing next-generation MPD equipment, adapting to evolving industry regulations and enhancing wellbore integrity solutions, Stasis helps drilling operators transition to safer, more environmentally responsible operations.

Contact Stasis Drilling Solutions today to discover how our MPD technologies, engineering expertise and wellbore integrity solutions can help you achieve environmentally responsible, regulation-compliant drilling operations.